Solar panels are made up of around 10 elements, including silicon, silver for the bus bars, copper for wiring, aluminum for the frames, ethylene-vinyl acetate (EVA) for the back sheet, plastics for the connectors and junction box, XLPE or PVC for cables, diodes, and others. Each solar module contains a set of solar cells, which are composed of semiconductor materials (i.e. silicon, Cadmium telluride, Copper indium gallium selenide among others).

In this blog post, I will discuss with you the key elements that comprise a solar panel. If you are highly interested in solar energy technology just like me, then you might want to continue reading this article detailing what solar panels are made up of.

Major Parts Of A Solar Panel: A Deeper Look

So, here are the major parts of a typical solar panel:

- Solar Cells

- Bus Bars

- Glass

- Wires

- Junction Box

- Frames

- Back Sheet

- Connectors

- Diodes

- Anti-Reflective Coating

These were already mentioned in the first paragraph, but here, we will discuss each of the key elements of a solar module and their functions one by one. In the video below, you will see how these solar panels are made.

The Function of Solar Cells in a Solar Module

Solar cells are the tiny, dark blue or black, rectangular or square-shaped components that you can see in a typical solar module. Also known as “PV Cells”, they are composed of semiconductors that collect solar energy from the Sun.

The conversion from sunlight into direct current (DC) electricity happens within this solar panel element. When AC power is needed, solar cells will need an inverter.

Each PV cell has the ability to transform photons from the sunlight into a flow of electrons that can deliver a certain amount of power in terms of Watts. This can range from 1.5 to 3.8 Watts depending on its cell type, dimension, and efficiency.

So, the total power capacity of a solar module is directly proportional to the number and efficiency of solar cells that it contains.

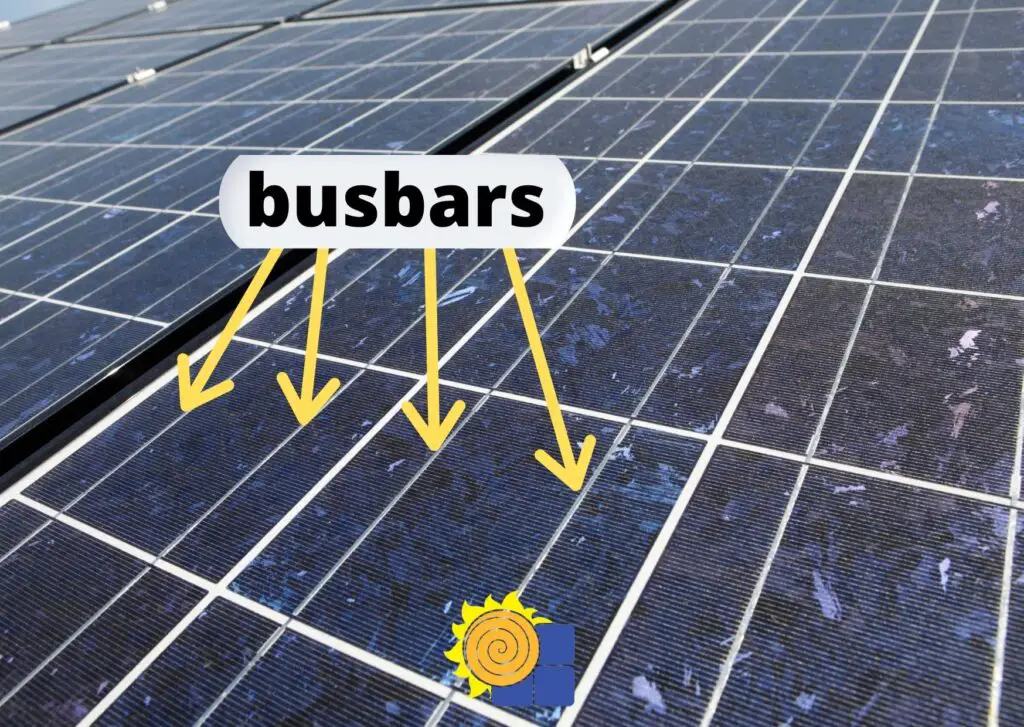

Bus Bars Inside the Solar Panels

To connect the solar cells together, you need to have solar panel bus bars. These are the conductors that join together the PV cells in so that the flow of electrons of the DC electricity will be collected into the output of a solar panel.

Solar panel bus bars are mostly made out of silver metal strips, which have the best electricity conductivity among other elements.

For most of the typical solar modules, you will be able to see these bus bars in the appearance of thin silver lines connecting a group of solar cells strategically. As solar energy is collected by the PV cells, the DC electricity flows through the silver conductors.

The generated electrical energy in small amounts from the solar cells flows through the solar panel bus bars before it goes to the solar panel output.

Glass: What purposes do they have for the solar module?

A solar panel’s front/back glass serves as a protective layer for the device. Tempered glass, also known as toughened glass, is the most commonly used material for solar modules for safety and protection purposes. This material is generally the main cause why solar panels becomes heavy.

High-quality solar modules undergo tests in order to determine the toughness of the glass and the equipment as a whole. Solar panel manufacturers will have their products undergo laboratory stress tests like:

- Hail storm tests

- Transport and environmental simulation on PV module shipping units

- Fire tests

- Snow load testing (non-uniform, heavy snow load)

- Corrosion tests

- Outdoor long-term tests in different climate zones

- Sand abrasion tests

The glass component comprises around 40-70 % of the whole solar panel. This is why I strongly recommend that you always ask for the test certificates from the supplier along with their warranty policies when you are planning to buy one. That way, you will be confident in the quality of the product.

Wires of Solar Panels

The wires that are used on the output side of solar modules are usually made of copper whether it be a bifacial module or monofacial panel.. They are also covered by XLPE or PVC for insulation and heat protection. As the electrons flow from the solar cells to the bus bars, they pass through the junction box diodes before going out of the solar panel cables.

Solar panels have both positive and negative terminals which can be compared to the battery’s electrical form. The difference is that the positive and negative wires are a part of the solar module itself.

The length of a solar panel’s cables is usually 500mm to 1000mm, but it may vary depending on the manufacturers. The typical placement of the cables can be found on the upper center part of the backside of the module. However, new solar module designs now place these cables on the central left and right sides of the panel.

What is the Purpose of Junction Box for Solar Panels?

The junction box of a solar module is usually fixed on the upper central backside of the module. This houses the solar panel diodes. The solar cables will usually be coming from this box as well.

Most solar panels have an IP (Ingress Protection) rating of IP67 or IP68 for their junction boxes. This allows for the water- and dust-proofing of the box so that the electronic parts inside it would not be easily damaged.

Solar Module Frames – What are they used for?

The solar module frame acts as the protective component to hold up the whole module and to increase its tensile strength. The solar module frame’s role lies in its mechanical attributes that impart several advantages:

- Grounding

- Storage

- Handling

- Fixation

- Windload Resistance

- Snow load Resistance

Since the majority of the solar panel is made up of glass, it is imperative to put something to protect it from being damaged. The good thing is that the solar panel frames are able to make it more durable and safer to install.

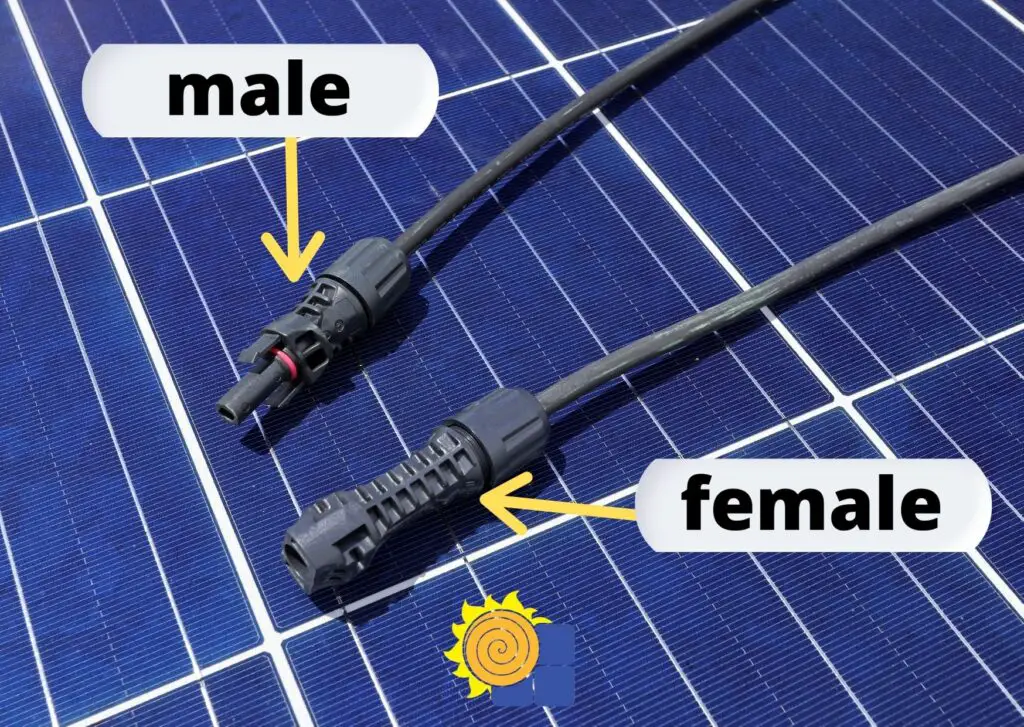

Solar Panel Connectors

To connect one solar module to another, that is to make a solar PV string, you will need to join them through their connectors.

Solar panel connectors are the black plastic that can be found on the tip of the module’s cable carrying its positive and negative output terminals. Both the male and female connectors house the metallic crimp contact, rubber water-seal and the seal retainer.

This component is also popularly known as an MC4 connector.

MC4 connectors are single-contact electrical connectors commonly used for connecting solar panels. The MC in MC4 stands for the manufacturer Multi-Contact (now Stäubli Electrical Connectors) and the 4 for the 4 mm diameter contact pin. MC4s allow strings of panels to be easily constructed by pushing the connectors from adjacent panels together by hand, but require a tool to disconnect them to ensure they do not accidentally disconnect when the cables are pulled. The MC4 and compatible products are universal in the solar market today, equipping almost all solar panels produced since about 2011.

Source: Wikipedia

Below, you can see how you would make a solar panel connector, from cable stripping to crimping and fixing of the connectors.

Diodes Inside Solar Panels: What are they used for?

Solar modules extensively use diodes for various purposes. Primarily, they are used to prevent the backflow of the current so that the electrons will only flow out of the module, not the other way around.

Solar panel diodes can be found inside the junction box.

They can also be used as a bypass device that increases the reliability of the whole module. What they do is that they bypass a series of solar cells in the event of shading or any failure in the particular group of PV cells.

Effects of Applying Anti-reflective Coating to Solar Panels

A solar cell that does not have an anti-reflective coating will lose as much as thirty-two percent (32%) of the solar energy through reflection. The application of thin-film coatings reduces the solar module’s reflectivity and increases the absorption of photons from the sunlight.

Anti-reflective coatings are used in a wide variety of applications where light passes through an optical surface, and low loss or low reflection is desired. Examples include anti-glare coatings on corrective lenses and camera lens elements and antireflective coatings on solar cells.

Source: Energy & Environmental Science

According to the study published in 2017 IEEE 44th Photovoltaic Specialist Conference (PVSC), “more than 4% of incident light is reflected from the standard front cover glass of photovoltaic (PV) modules” without anti-reflective coating.

Solar Panels and Silicon: How Is A Solar Panel Made?

There are numerous elements collected together when manufacturing a solar module. Following are the most common materials that you can find in a solar panel:

- Silicon

- Copper

- Silver

- Aluminum

Fun Fact: What are solar modules made out of? We can say that a solar module is made out of sand since the majority of its components are silicon. The raw sands undergo certain processes and transform into silicon wafers and glass to fabricate solar modules.

Silicon and Solar Panels: Why Use Silicon?

Why do we use silicon for solar panels? Silicon is one of the most abundantly available resources that you can find on the surface of the Earth, the sand. Additionally, the process of converting sand into silicon is cost-efficient. So, why not use them to produce a sustainable product, right?

When the raw materials are taken out of the sand, they are transformed into silicon ingots through the melting process. It reaches above 1420°C. The process dissolves the crystal and dopant mixture. Then, the crystal seed is put on top of the melt without touching the surface.

Silicon Wafers and Solar Cells

Once the crystal seed has become silicon ingots, the next step of the manufacturing process is to slice them into thin disks. These are the silicon wafers. Silicon wafers are treated to create solar cells.

Moreover, metal conductors are added to them as well. These conductors are the grid-like matrix, which you can see on the surface of the solar cells. This conductor matrix would ensure that electrons will efficiently travel into the output cables, thus, producing electricity flow.

Are Solar Panels Made From Coal?

Solar panels are made out of different types of materials but coal is not one of them. Moreover, some people argue that solar modules are not green as they represent. That’s because they assume that coal is being used for the production of solar panels.

Coal is not directly a part of a solar panel’s composition. However, you will still be able to see how coal is being used by some of the solar module manufacturers during the manufacturing process. The burning of coal could be used during the energy generation process. Factories and manufacturing plants need energy for the manufacturing of solar panels.

Silicon Vs. Coal

Even though sand is abundantly available as raw material, we still need heat to convert that into silicon. For such processes, some solar panel manufacturers are using coal to produce the heat energy for the melting process.

This is something that you will need to be mindful of, especially when you are purchasing solar modules.

Negative Impact of Coal to Solar Panel Industry

If you are concerned about the negative impact that is created by the burning of coal, you should stick to the solar panels that are manufactured without coal burning.

Final Thoughts: What Is A Solar Panel Made Up Of?

As stated in the first part of this article, around 10 elements comprise a whole solar panel, but it is mostly silicon. Each component has its own purposes and functions.

Additionally, although coal is not one of the components of a solar module, it is still possible that they are used by some manufacturers for the energy requirement during the process.

Finally, it is always amazing to realize how a combination of sands and other raw materials could produce a sustainable energy-generating product. As solar panel prices dramatically go down, it will be a smart move towards a sustainable way of living!

Sign up to our newsletter now and be part of the Solar Powered Fam!

Nice blog regarding solar panels. Keep us updated!!